Engineering

WaterSaver water fittings are available with a choice of three valve cartridges. All three cartridges are dimensionally identical and therefore totally interchangeable.

All cartridges are completely self-contained and include all working components of the valve mechanism. No wearing components are separate from the valve unit. The faucet body itself is thus not subject to wear, making it virtually everlasting. Replacement of the cartridge instantly produces a “new” tap or valve.

Compression Unit (BT Series)

Cartridge has outer serrations to lock into faucet body. Unit cannot turn or move in faucet body, even with wrist blade handles.

Molded PTFE stem packing seals valve stem. Packing prevents leakage over hundreds of thousands of cycles. Adjustable packing nut permits take-up of wear.

Valve seat is stainless steel. Ultra-hard seating surface provides durable service in even the harshest water conditions. Seat will outperform brass or other materials.

Hard synthetic rubber valve disc provides positive shut-off of water flow. Valve does not have “spongy” feel.

Manual and self-closing valve units are interchangeable. Field conversion can be accomplished in seconds.

Compression Unit with Adjustable Volume Control (BTA Series)

Same construction features as compression unit (stainless steel seat, PTFE stem packing, etc.).

Adjustable volume control can be adjusted to regulate size of inlet port of valve. Volume control may be used to compensate for high water pressure and conserve water.

Ceramic Disc Unit (BTC Series)

Rotating ceramic discs control flow of water. Discs are ultra-hard and self-lubricating for durable service.

180 degree rotation from closed to open to permit metering of flow. Available with optional 90 degree rotation for use with wrist blade handles.

Wear-resistant thrust washer is low friction for smooth opening and closing of valve.

Internal baffles reduce noise as water flows through valve.

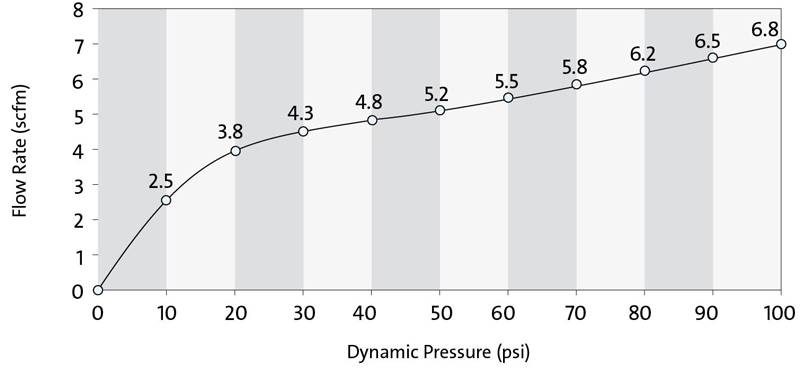

Needle Valve Flow Chart

Note: Flow rate is based upon valve with serrated hose end installed. Flow rate may vary if other type of outlet fitting (e.g. quick connect, compression fitting, etc.) is installed.